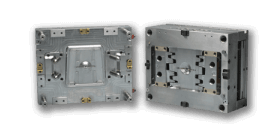

- Prototype Molding

- Bridge Molding

- Rapid Production

| Prototype Molding | Bridge Molding | Rapid Production | |

$ | $ /Only | $ /Only | |

| Lead-time

Typical time from project start to sample parts

| 2-4 weeks | 3-6 weeks | 4-8 weeks |

| Price | Starting at $899 | $$ | $$$ |

| Typical Tool Life (cycles) | 10k+ | 300k+ | 500k to 10M+ |

| Sharp Corners

We use advanced EDM technology so your parts can have sharp corners

| |||

| Undercuts

Slides, lifters & male threads

| Manual/Automatic | Automatic | Automatic |

| Threaded Holes

Requires unscrewing mechanism

| Manual | Automatic | Automatic |

| Insert Molding | |||

| Over Molding | Learn More | Learn More | Learn More | Learn More |